Light Spectrum Optimization: Indoor THCA Cultivation at Oregon Hemp Flower Farm

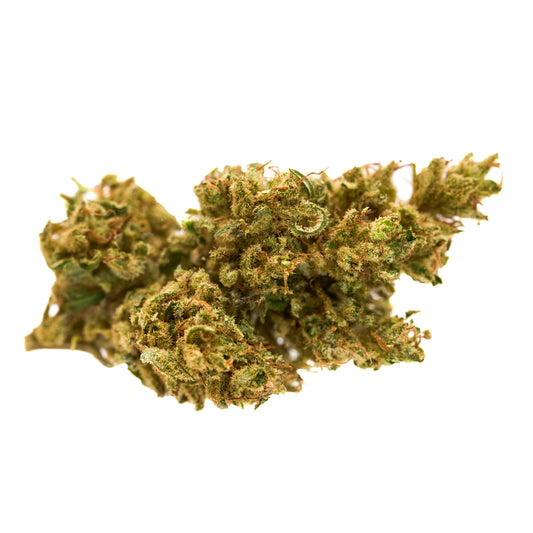

The cultivation of high-quality THCA hemp flower has evolved dramatically with advances in lighting technology and controlled environment agriculture. At Oregon Hemp Flower Farm, we've pioneered sophisticated approaches to indoor THCA flower production that leverage cutting-edge light spectrum optimization to maximize both yield and cannabinoid potency. Our commitment to excellence in premium indoor THCA cultivation represents the intersection of horticultural science, advanced technology, and sustainable growing practices.

The science of photosynthesis hemp cultivation requires a deep understanding of how different light wavelengths interact with plant biology to influence growth patterns, metabolic processes, and ultimately, the production of therapeutic compounds. Through years of research and practical application, we've developed comprehensive protocols for lighting technology THCA production that consistently deliver superior results compared to traditional growing methods.

Understanding THCA and Its Cultivation Requirements

Tetrahydrocannabinolic acid (THCA) represents the precursor compound to THC, naturally occurring in raw cannabis and hemp plants before decarboxylation through heat or time. Unlike its psychoactive counterpart, THCA offers potential therapeutic benefits without intoxicating effects, making it increasingly valuable for medical applications and wellness products. The biosynthesis of THCA within hemp plants is heavily influenced by environmental factors, with lighting conditions playing a particularly crucial role in determining final cannabinoid profiles and concentrations.

THCA flower cultivation demands precise environmental control to optimize the complex biochemical pathways responsible for cannabinoid production. Light serves as both the primary energy source for photosynthesis and a regulatory signal that influences gene expression, hormone production, and secondary metabolite synthesis. Understanding these relationships allows cultivators to manipulate lighting parameters to enhance THCA production while maintaining healthy plant development and robust flower formation.

The metabolic pathways involved in THCA biosynthesis begin with the production of cannabigerolic acid (CBGA), often called the "mother cannabinoid," which is then converted to THCA through the action of specific enzymes. Light quality, intensity, and photoperiod all influence these enzymatic processes, with different wavelengths triggering various physiological responses that ultimately affect cannabinoid concentrations in mature flowers.

The Science of Light Spectrum in Hemp Cultivation

Light spectrum hemp cultivation relies on understanding how different wavelengths of electromagnetic radiation affect plant physiology and biochemistry. The photosynthetic process primarily utilizes light in the 400-700 nanometer range, known as photosynthetically active radiation (PAR), but plants also respond to wavelengths outside this range that influence morphology, flowering, and secondary metabolite production.

Blue light wavelengths (400-500nm) are crucial for vegetative growth, promoting compact plant structure, strong stems, and healthy leaf development. These wavelengths also play important roles in stomatal regulation and the production of protective compounds that help plants resist environmental stresses. During vegetative growth phases, higher ratios of blue light encourage robust plant architecture that can support heavy flower production during later growth stages.

Red light wavelengths (600-700nm) are highly efficient for photosynthesis and are particularly important during flowering phases. These wavelengths promote stem elongation, leaf expansion, and flower development, making them essential for maximizing yield potential. Far-red light (700-800nm) influences plant architecture and flowering responses, while also affecting the shade avoidance response that can influence plant spacing and canopy management strategies.

Green light (500-600nm), while less efficiently absorbed than red or blue wavelengths, penetrates deeper into plant canopies and can contribute to photosynthesis in lower leaves. Recent research has also shown that green light can influence stomatal behavior and may play roles in stress responses and photomorphogenic processes that affect secondary metabolite production.

Advanced LED Technology for THCA Cultivation

LED growing THCA has revolutionized indoor hemp cultivation by providing unprecedented control over light quality, quantity, and timing. Modern LED systems offer significant advantages over traditional lighting technologies, including improved energy efficiency, reduced heat production, longer lifespans, and the ability to customize spectral output for specific growth phases and cultivation goals.

Full-spectrum LED systems designed for hemp cultivation typically incorporate multiple LED chip types to provide comprehensive wavelength coverage. High-quality systems include dedicated blue, red, white, and often far-red and UV diodes that can be independently controlled to create custom light recipes for different growth stages. This flexibility allows cultivators to optimize lighting conditions for vegetative growth, flower initiation, flower development, and final maturation phases.

The efficacy of modern LED systems, measured in photons per unit of electrical energy consumed, has improved dramatically in recent years. High-end horticultural LED fixtures now achieve photosynthetic photon efficacy (PPE) ratings exceeding 2.7 μmol/J, representing significant improvements in energy efficient growing compared to traditional HID lighting systems. This efficiency translates to lower operating costs and reduced environmental impact while maintaining or improving growing results.

Heat management represents another crucial advantage of LED technology for indoor cultivation Oregon operations. Traditional high-intensity discharge (HID) lighting systems produce substantial heat that requires expensive cooling systems to maintain optimal growing temperatures. LED systems produce significantly less waste heat, allowing for closer placement to plant canopies and reducing HVAC requirements, which contributes to overall system efficiency and cost-effectiveness.

Spectrum Optimization Strategies

Spectrum optimization for THCA cultivation involves developing lighting protocols that maximize cannabinoid production while maintaining healthy plant development throughout all growth phases. This process requires understanding the complex interactions between light quality, plant physiology, and biochemical processes that control THCA synthesis and accumulation.

During vegetative growth phases, our lighting protocols emphasize blue-rich spectra that promote compact, robust plant structure while encouraging the development of numerous branching sites that will eventually support flower production. The specific blue-to-red ratios are carefully calibrated to balance vegetative vigor with structural integrity, ensuring plants develop the framework necessary to support heavy flower loads without requiring excessive structural support.

As plants transition to flowering phases, spectral compositions shift to emphasize red wavelengths that promote flower initiation and development. However, the transition is gradual rather than abrupt, allowing plants to adapt to changing light conditions without stress responses that could negatively impact cannabinoid production. Far-red wavelengths are strategically incorporated to influence flowering responses and plant architecture, while UV wavelengths may be introduced during specific phases to stimulate protective compound production.

The timing and intensity of spectral changes are carefully coordinated with other environmental factors including temperature, humidity, and nutrition programs. This integrated approach ensures that lighting optimization works synergistically with all aspects of the growing environment to maximize THCA production while maintaining plant health and vigor throughout the cultivation cycle.

Photosynthesis and Cannabinoid Production

The relationship between photosynthesis hemp processes and cannabinoid production is fundamental to understanding how lighting optimization affects THCA accumulation. Photosynthesis provides the energy and carbon building blocks necessary for all plant metabolic processes, including the biosynthesis of secondary metabolites like cannabinoids.

Light-dependent reactions of photosynthesis occur in the chloroplasts, where photons are captured by photosystem complexes and converted to chemical energy in the form of ATP and NADPH. These energy carriers are then used in the Calvin cycle to fix atmospheric carbon dioxide into organic compounds that serve as precursors for all plant biomolecules, including the complex molecules that eventually become THCA.

The efficiency of photosynthetic processes directly influences the plant's capacity to produce secondary metabolites. When photosynthesis is optimized through proper lighting conditions, plants generate sufficient energy and carbon precursors to support both primary growth processes and secondary metabolite production. Conversely, sub-optimal lighting conditions can limit photosynthetic capacity, forcing plants to prioritize survival over secondary metabolite production.

Recent research has revealed that specific wavelengths can directly influence the expression of genes involved in cannabinoid biosynthesis, independent of their effects on photosynthesis. This discovery has opened new avenues for optimal lighting THCA production that focus on manipulating gene expression patterns through targeted spectral applications.

Controlled Environment Agriculture Systems

Controlled environment agriculture represents the pinnacle of precision growing, allowing cultivators to optimize every aspect of the plant's environment for maximum productivity and quality. In THCA cultivation, environmental control extends beyond simple temperature and humidity management to include precise manipulation of lighting, atmospheric composition, nutrition delivery, and root zone conditions.

Advanced climate control systems integrate lighting management with heating, cooling, dehumidification, and air circulation to maintain optimal growing conditions throughout day and night cycles. These systems use sophisticated sensors and control algorithms to maintain precise environmental parameters while minimizing energy consumption and operational costs.

Air circulation and exchange systems ensure proper distribution of conditioned air throughout growing spaces while managing humidity levels and preventing the accumulation of plant pathogens. Carbon dioxide supplementation systems can enhance photosynthetic rates when properly coordinated with lighting and temperature management, potentially increasing both growth rates and cannabinoid production.

Hydroponic and soilless growing systems provide precise control over root zone conditions, allowing for optimal nutrient delivery and root health maintenance. These systems can be automated to adjust nutrient concentrations and pH levels based on plant growth phases and environmental conditions, ensuring that plants always have access to the nutrients needed for maximum THCA production.

Comparing Indoor, Outdoor, and Greenhouse Production

The choice between indoor THCA flower, outdoor THCA flower, and greenhouse THCA flower production involves balancing quality control, production costs, and market demands. Each production method offers distinct advantages and challenges that must be carefully considered when developing cultivation strategies.

Indoor production provides maximum environmental control, allowing for year-round cultivation cycles and consistent product quality regardless of external weather conditions. The ability to precisely control lighting conditions enables optimization of cannabinoid production and flower quality that may not be achievable with other production methods. However, indoor production typically requires higher initial capital investments and ongoing operational costs, particularly for lighting and climate control systems.

Outdoor production leverages natural sunlight and environmental conditions to reduce operational costs while potentially achieving high yields under favorable conditions. Natural sunlight provides a full spectrum of wavelengths that can support robust plant development and cannabinoid production. However, outdoor production is subject to weather variability, seasonal limitations, and potential pest and disease pressures that can impact both yield and quality consistency.

Greenhouse production offers a compromise between the control of indoor systems and the cost-effectiveness of outdoor production. Modern greenhouse systems can provide significant environmental control while utilizing natural sunlight to reduce lighting costs. Supplemental lighting systems can extend growing seasons and optimize light conditions during periods of low natural light availability.

Energy Efficiency and Sustainability

Energy efficient growing has become increasingly important as the hemp industry matures and faces scrutiny regarding environmental impact. LED lighting technology has dramatically improved the energy efficiency of indoor cultivation operations, but further optimization is possible through integrated system design and smart control technologies.

Advanced lighting control systems can adjust light intensity and spectral composition based on real-time plant responses and environmental conditions. These systems use sensors to monitor plant stress indicators, growth rates, and environmental parameters to optimize lighting delivery while minimizing energy consumption. Machine learning algorithms can analyze historical data and plant responses to continuously improve lighting protocols and reduce energy waste.

Renewable energy integration represents another avenue for improving the sustainability of THCA cultivation operations. Solar panel systems can provide clean electricity for LED lighting systems, particularly in regions with abundant solar resources. Battery storage systems can help manage energy demand and take advantage of off-peak electricity rates while ensuring consistent power supply for critical growing systems.

Heat recovery systems can capture waste heat from LED fixtures and other equipment to reduce heating costs during cooler periods. While LED systems produce less waste heat than traditional lighting, the heat they do produce can still be utilized for space heating or other applications, improving overall system efficiency.

Quality Control and Testing

Quality control in premium indoor THCA production requires comprehensive testing protocols that verify cannabinoid potency, purity, and safety. Advanced analytical techniques including high-performance liquid chromatography (HPLC) and gas chromatography-mass spectrometry (GC-MS) provide precise quantification of THCA and other cannabinoids while screening for contaminants and adulterants.

Terpene profiling represents another crucial aspect of quality control, as these aromatic compounds contribute significantly to the therapeutic effects and sensory characteristics of hemp flowers. Advanced analytical methods can identify and quantify dozens of individual terpenes, allowing cultivators to optimize growing conditions for specific terpene profiles that complement THCA content.

Microbiological testing ensures that finished products are free from harmful bacteria, mold, and yeast that could pose health risks to consumers. These tests are particularly important for indoor cultivation operations where high humidity conditions could promote microbial growth if not properly managed.

Heavy metal and pesticide residue testing verifies that products meet safety standards and regulatory requirements. Indoor cultivation systems typically have better control over these contaminants compared to outdoor production, but regular testing remains essential for quality assurance and regulatory compliance.

Technology Integration and Automation

Modern grow lights hemp cultivation increasingly relies on integrated technology systems that automate many aspects of environmental control and plant management. These systems can monitor plant health, environmental conditions, and system performance while automatically adjusting parameters to maintain optimal growing conditions.

Sensor networks throughout growing facilities continuously monitor temperature, humidity, light levels, CO2 concentrations, and other critical parameters. This data is processed by central control systems that can identify trends, predict potential problems, and automatically adjust environmental controls to maintain optimal conditions.

Automated irrigation and nutrition systems can deliver precise amounts of water and nutrients based on plant growth stages, environmental conditions, and real-time monitoring of root zone conditions. These systems help optimize plant nutrition while minimizing waste and reducing labor requirements.

Data logging and analysis systems track all aspects of cultivation operations, creating detailed records that can be analyzed to identify optimization opportunities and ensure consistency between production cycles. This data-driven approach enables continuous improvement in cultivation protocols and helps maintain consistent product quality.

Future Developments and Innovations

The future of lighting technology THCA cultivation promises continued advances in efficiency, control, and automation. Emerging LED technologies including quantum dot LEDs and organic LEDs may offer improved spectral control and efficiency compared to current semiconductor-based systems.

Artificial intelligence and machine learning applications are beginning to transform cultivation management by analyzing complex datasets to identify optimization opportunities and predict plant responses to environmental changes. These technologies may eventually enable fully autonomous cultivation systems that can operate with minimal human intervention while consistently producing high-quality THCA products.

Spectral tuning technologies that can adjust light output in real-time based on plant feedback may enable unprecedented precision in lighting optimization. These systems could potentially respond to plant stress signals or growth indicators by automatically adjusting spectral composition to optimize plant responses.

Wireless sensor networks and Internet of Things (IoT) technologies are making it easier and more cost-effective to monitor and control growing environments. These technologies enable more granular monitoring and control while reducing installation and maintenance costs for cultivation facilities.

Conclusion

The cultivation of premium THCA hemp flower through advanced lighting optimization represents the convergence of horticultural science, engineering innovation, and sustainable agriculture practices. At Oregon Hemp Flower Farm, our experience with indoor cultivation Oregon operations has demonstrated that careful attention to light spectrum optimization can dramatically improve both the quantity and quality of THCA production while maintaining energy efficiency and environmental sustainability.

The sophisticated interplay between light wavelengths, plant physiology, and cannabinoid biosynthesis requires a deep understanding of both the science and the practical applications of modern growing technologies. Our success with LED growing THCA demonstrates that investment in advanced lighting systems and control technologies can deliver superior results that justify the initial costs through improved yields, enhanced quality, and reduced operational expenses.

As the hemp industry continues to evolve and mature, the importance of scientific approaches to cultivation will only increase. Consumers and regulators alike are demanding higher standards for product quality, consistency, and safety, while environmental concerns are driving demand for more sustainable production methods. The integration of advanced lighting technologies with comprehensive environmental control systems represents the future of commercial hemp cultivation, offering the precision and consistency needed to meet these evolving demands.

The journey toward optimal THCA flower cultivation continues to evolve as new technologies emerge and our understanding of plant biology deepens. By maintaining our commitment to innovation, quality, and sustainability, Oregon Hemp Flower Farm will continue to lead the industry in producing the highest quality THCA products while setting new standards for environmental responsibility and operational efficiency. Our success serves as a model for the industry, demonstrating that advanced cultivation techniques can deliver superior products while contributing to the sustainable growth of the hemp industry.

Leave a comment

Please note, comments need to be approved before they are published.