THCA Flower Drying Techniques: Oregon's Climate-Controlled Methods at Oregon Hemp Flower Farm

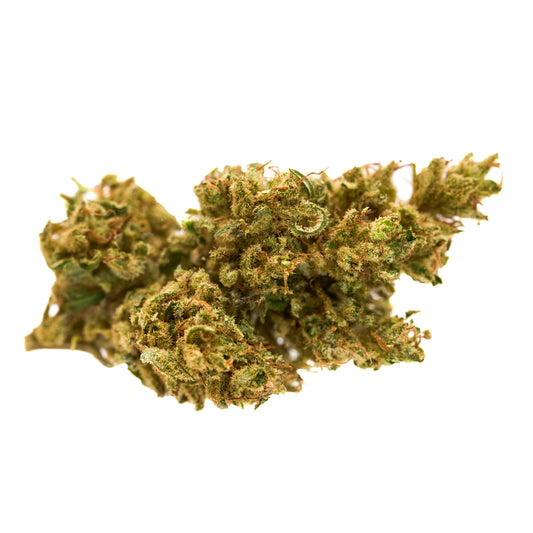

Oregon's diverse climate presents unique challenges and opportunities for cannabis cultivation, particularly when it comes to drying THCA hemp flower. At Oregon Hemp Flower Farm, the art and science of thca flower drying oregon has been refined through years of experience and cutting-edge technology. The Pacific Northwest's variable weather conditions—from coastal humidity to high desert dryness—demand sophisticated approaches to preserve the delicate cannabinoids and terpenes that make THCA flower so valuable.

The importance of proper drying cannot be overstated in cannabis cultivation. This critical post-harvest phase determines whether months of careful growing will result in premium product or disappointing waste. Oregon Hemp Flower Farm has mastered the delicate balance required for proper drying techniques, creating controlled drying environment systems that consistently produce exceptional results regardless of external weather conditions.

Understanding Oregon's Climate Challenges

Oregon's climate diversity is both a blessing and a challenge for cannabis cultivators. The state's western regions experience maritime influences with high humidity levels, particularly during fall harvest seasons when moisture can exceed 80%. Eastern Oregon presents the opposite challenge, with arid conditions that can drop humidity below 20%. These extremes make natural air-drying unreliable and potentially destructive to valuable THCA flower crops.

Temperature fluctuations compound these humidity challenges. Coastal areas might see daily temperature swings of 20-30 degrees Fahrenheit, while inland valleys can experience even greater variations. Such instability threatens the delicate chemical compounds in freshly harvested THCA flower, potentially leading to cannabinoid degradation, terpene loss, or dangerous mold development.

Climate control hemp operations in Oregon must account for seasonal variations that can dramatically impact drying conditions. Spring harvests might contend with lingering winter moisture, while fall harvests face the challenge of incoming Pacific storm systems. These variables have driven Oregon Hemp Flower Farm to develop sophisticated controlled drying environment systems that maintain consistency regardless of external conditions.

The microclimate within drying facilities becomes crucial when external conditions prove unreliable. Oregon's experienced cultivators understand that successful thca flower drying oregon requires creating an artificial environment that can be precisely controlled and monitored. This approach ensures that every batch of THCA flower receives optimal treatment, preserving the plant's valuable compounds while preventing spoilage.

The Science of THCA Flower Drying

THCA (tetrahydrocannabinolic acid) is the non-psychoactive precursor to THC, naturally occurring in fresh cannabis plants. This compound is particularly sensitive to environmental conditions during the drying process. Understanding the science behind proper drying techniques is essential for preserving THCA content while developing the desired characteristics that consumers expect from premium flower.

The drying process involves carefully removing moisture from plant material while maintaining the integrity of cannabinoids and terpenes. Fresh cannabis plants typically contain 75-85% water content, which must be reduced to approximately 10-15% for optimal storage and consumption. This moisture reduction must occur gradually and under controlled conditions to prevent rapid cellular breakdown that could destroy valuable compounds.

Temperature controlled drying plays a crucial role in this process. Excessive heat accelerates moisture removal but also promotes terpene evaporation and cannabinoid degradation. Temperatures above 70°F can cause significant terpene loss, while temperatures below 60°F may slow drying to the point where mold becomes a serious risk. Oregon Hemp Flower Farm maintains precise temperature ranges that optimize drying speed while preserving plant chemistry.

Humidity control hemp operations must balance several competing factors. High humidity slows drying and increases mold risk, while low humidity can cause overly rapid moisture loss that damages plant structures and promotes terpene volatilization. The ideal humidity range for thca flower drying oregon typically falls between 45-55% relative humidity, with careful monitoring to prevent dangerous fluctuations.

Air circulation represents another critical component of optimal drying conditions. Proper airflow ensures even moisture removal throughout the drying chamber while preventing stagnant air pockets where mold could develop. However, excessive air movement can accelerate terpene loss and create uneven drying patterns. Oregon Hemp Flower Farm's systems provide gentle, consistent air circulation that promotes uniform drying without compromising flower quality.

Advanced Climate Control Systems

Modern professional drying thca operations rely on sophisticated environmental control systems that can maintain precise conditions regardless of external weather. Oregon Hemp Flower Farm has invested in state-of-the-art climate control hemp technology that monitors and adjusts multiple environmental parameters simultaneously.

HVAC systems designed specifically for cannabis drying provide precise temperature control within narrow ranges. These systems often incorporate multiple zones that can be independently controlled, allowing different batches of flower to receive customized treatment based on their specific needs. Temperature controlled drying systems include redundant sensors and backup equipment to prevent system failures that could damage valuable crops.

Dehumidification equipment works in conjunction with temperature control to maintain optimal humidity control hemp conditions. Commercial-grade dehumidifiers can remove thousands of gallons of moisture daily while maintaining precise relative humidity levels. These systems often include heat recovery features that capture energy from the dehumidification process to assist with temperature control, improving overall efficiency.

Air filtration systems protect drying flower from contaminants while maintaining the controlled drying environment. HEPA filtration removes particles, spores, and other potential contaminants that could compromise flower quality or safety. Some facilities incorporate UV sterilization or ozone treatment to further ensure clean air quality throughout the drying process.

Monitoring and control systems provide real-time data on all environmental parameters while maintaining detailed logs for quality assurance purposes. Modern professional drying thca facilities utilize computer-controlled systems that can automatically adjust conditions based on predetermined parameters, ensuring consistent results across multiple drying cycles.

Indoor THCA Flower Drying Methods

Indoor thca flower drying provides the ultimate control over environmental conditions, making it the preferred method for premium cannabis operations. Oregon Hemp Flower Farm's indoor drying facilities represent the pinnacle of controlled drying environment technology, capable of maintaining precise conditions regardless of external weather.

Indoor drying rooms are typically designed with specific dimensional ratios that promote optimal air circulation patterns. Ceiling heights, wall spacing, and ventilation placement all contribute to creating uniform conditions throughout the drying space. Premium indoor thca operations often feature multiple smaller rooms rather than single large spaces, allowing for batch segregation and customized treatment protocols.

Rack systems within indoor drying rooms maximize space utilization while ensuring adequate air circulation around each drying flower. Materials must be chosen carefully to avoid any chemical interactions with the drying cannabis while providing durability and easy cleaning. Stainless steel and food-grade plastics are commonly used in professional drying thca facilities.

Lighting within drying rooms requires careful consideration. While complete darkness isn't necessary, direct light can degrade cannabinoids and should be minimized. Many facilities use low-intensity LED lighting that provides adequate visibility for monitoring without contributing significant heat or photodegradation risks.

Security systems in indoor drying facilities must balance access control with monitoring requirements. Indoor thca flower operations require regular inspection and adjustment, but access must be carefully controlled to prevent contamination or theft. Modern facilities often incorporate remote monitoring capabilities that reduce the need for physical access while maintaining oversight.

Outdoor THCA Flower Considerations

While outdoor thca flower cultivation can produce exceptional results, the drying phase presents unique challenges that require careful planning and execution. Oregon's variable climate makes outdoor drying particularly challenging, often necessitating hybrid approaches that combine outdoor growing with controlled drying environment techniques.

Outdoor thca flower drying must contend with uncontrollable environmental factors including temperature fluctuations, humidity changes, precipitation, and wind conditions. These variables can change rapidly and dramatically, potentially destroying entire harvests if not properly managed. Successful outdoor operations often incorporate covered drying areas or temporary structures that provide some environmental control.

Weather monitoring becomes critical for outdoor thca flower operations. Advanced forecasting and real-time weather data help cultivators make informed decisions about when to harvest and how to protect drying flower from adverse conditions. Some operations maintain both outdoor and indoor drying capabilities to provide flexibility based on weather conditions.

Pest management takes on additional importance in outdoor drying scenarios. Birds, insects, and other wildlife can damage or contaminate drying flower, requiring protective measures that don't interfere with proper air circulation. Screening, netting, and other barriers must be carefully designed to provide protection while maintaining optimal drying conditions.

The economics of outdoor thca flower drying often favor hybrid approaches that combine outdoor cultivation with controlled drying environment finishing. This strategy allows cultivators to benefit from natural growing conditions while ensuring consistent drying quality through artificial environmental control.

Greenhouse THCA Flower Drying

Greenhouse thca flower operations offer a middle ground between fully outdoor and indoor cultivation, providing some environmental control while maintaining connection to natural conditions. Oregon Hemp Flower Farm's greenhouse facilities demonstrate how this approach can be optimized for consistent thca flower drying oregon results.

Greenhouse structures can be equipped with supplemental climate control hemp systems that provide additional environmental management during critical drying periods. Fans, heaters, dehumidifiers, and other equipment can be integrated into greenhouse designs to create controlled drying environment conditions when needed.

Ventilation systems in greenhouse thca flower facilities must balance natural air exchange with controlled environmental conditions. Automated vent systems can respond to changing conditions by adjusting air flow rates and patterns. These systems often incorporate sensors that monitor both internal and external conditions to optimize ventilation decisions.

Humidity management in greenhouse settings requires careful attention to both natural and artificial sources of moisture. Plant transpiration, soil evaporation, and external weather all contribute to internal humidity levels. Greenhouse thca flower operations often incorporate moisture barriers, drainage systems, and supplemental dehumidification to maintain optimal drying conditions.

Temperature control in greenhouse environments must account for solar heat gain, thermal mass effects, and natural cooling processes. Supplemental heating and cooling systems can provide fine-tuning capabilities when natural conditions prove insufficient. Some facilities incorporate thermal screens or other passive systems to help manage temperature fluctuations.

Quality Preservation Techniques

Preserve quality drying requires attention to multiple factors beyond basic environmental control. Oregon Hemp Flower Farm has developed comprehensive protocols that address every aspect of the drying process to ensure maximum preservation of THCA, terpenes, and other valuable compounds.

Harvesting timing plays a crucial role in preserve quality drying outcomes. Trichome development, cannabinoid profiles, and plant maturity all influence how flower responds to drying conditions. Optimal harvest timing varies by strain and growing conditions, requiring experienced judgment to maximize drying success.

Handling procedures during the transition from growing to drying can significantly impact final quality. Mechanical damage, contamination, and stress during harvest and initial processing can compromise the plant's ability to dry properly. Proper drying techniques begin with careful handling that preserves plant integrity throughout the process.

Trimming decisions affect both drying characteristics and final product quality. The amount of leaf material left on flowers influences drying rates, final appearance, and storage characteristics. Professional drying thca operations often experiment with different trimming approaches to optimize results for specific strains and market requirements.

Monitoring protocols ensure that drying progress meets quality standards throughout the process. Regular testing of moisture content, visual inspection for mold or other issues, and assessment of aromatic development help identify potential problems before they become serious. Preserve quality drying requires vigilant oversight and rapid response to any deviations from optimal conditions.

Oregon-Specific Drying Methods

Oregon drying methods have evolved to address the state's unique climate challenges while taking advantage of its natural benefits. Oregon Hemp Flower Farm's techniques reflect years of experience working with local conditions and represent best practices for thca flower drying oregon operations.

Seasonal adaptation strategies recognize that optimal drying approaches change throughout the year. Spring harvests might require additional dehumidification to combat coastal moisture, while summer harvests could benefit from evaporative cooling systems. Oregon drying methods must remain flexible to accommodate these seasonal variations.

Regional climate differences within Oregon require customized approaches for different growing areas. Coastal operations face different challenges than those in the Columbia River Gorge or eastern Oregon high desert. Successful thca flower drying oregon operations develop expertise specific to their local microclimate conditions.

Integration with local weather patterns allows experienced operators to predict and prepare for challenging drying conditions. Understanding how Pacific storm systems, high pressure ridges, and other weather phenomena affect drying conditions enables proactive management strategies. Oregon drying methods often incorporate weather-based decision-making protocols.

Collaboration within Oregon's cannabis community has led to shared knowledge and improved proper drying techniques throughout the state. Industry associations, educational programs, and informal networks help spread best practices for thca flower drying oregon, raising quality standards across the entire industry.

Professional Equipment and Technology

Professional drying thca operations require specialized equipment designed specifically for cannabis processing. Oregon Hemp Flower Farm utilizes state-of-the-art technology that ensures consistent results while maximizing efficiency and product quality.

Environmental monitoring systems provide real-time data on temperature, humidity, air flow, and other critical parameters. These systems often include data logging capabilities that maintain detailed records for quality assurance and regulatory compliance. Professional drying thca facilities typically incorporate multiple redundant sensors to ensure accurate readings and prevent system failures.

Automated control systems can adjust environmental conditions based on predetermined parameters or operator input. These systems can respond to changing conditions faster than human operators while maintaining more precise control over environmental variables. Climate control hemp automation reduces labor requirements while improving consistency.

Air handling equipment designed for cannabis applications provides optimal circulation patterns while minimizing noise and energy consumption. Variable speed fans, ductwork design, and air distribution systems all contribute to creating optimal drying conditions throughout the drying space.

Quality testing equipment allows operators to monitor drying progress and final product characteristics. Moisture meters, microscopes for trichome examination, and other analytical tools help ensure that proper drying techniques are producing desired results.

Optimal Drying Conditions

Achieving optimal drying conditions requires balancing multiple environmental factors while considering the specific characteristics of each THCA flower batch. Oregon Hemp Flower Farm's protocols address every aspect of environmental control to ensure consistent, high-quality results.

Temperature ranges for optimal drying conditions typically fall between 60-70°F, with precise control to prevent fluctuations that could stress the drying plant material. Different strains may require slight temperature adjustments based on their specific characteristics and desired outcomes. Temperature controlled drying systems must maintain stability while allowing for these customizations.

Humidity levels for optimal drying conditions generally range from 45-55% relative humidity, though specific targets may vary based on ambient conditions and drying facility characteristics. Humidity control hemp systems must respond quickly to changes while avoiding overcorrection that could create unstable conditions.

Air circulation requirements for optimal drying conditions must provide adequate movement to prevent stagnant air pockets while avoiding excessive flow that could accelerate terpene loss. Air velocity, direction, and distribution patterns all contribute to creating uniform drying conditions throughout the facility.

Duration considerations for optimal drying conditions typically range from 7-14 days, depending on flower density, environmental conditions, and desired final characteristics. Proper drying techniques require careful monitoring to determine when optimal moisture levels have been achieved without over-drying.

Quality Assurance and Testing

Professional drying thca operations implement comprehensive quality assurance programs that monitor every aspect of the drying process. Oregon Hemp Flower Farm's protocols ensure that each batch meets strict quality standards while maintaining detailed documentation for regulatory compliance.

Moisture content testing provides the primary metric for determining when drying is complete. Target moisture levels typically range from 10-15%, though specific requirements may vary based on intended use and storage conditions. Preserve quality drying requires accurate moisture measurement to prevent under-drying or over-drying.

Cannabinoid analysis during and after drying helps ensure that proper drying techniques are preserving valuable compounds. THCA content, CBD levels, and other cannabinoids should remain stable throughout the drying process when conditions are properly maintained. Regular testing identifies any degradation issues before they affect entire batches.

Terpene preservation assessment measures the retention of aromatic compounds that contribute to flavor, aroma, and therapeutic effects. Optimal drying conditions should minimize terpene loss while achieving proper moisture levels. Gas chromatography or other analytical methods can quantify terpene retention rates.

Microbial testing ensures that dried flower meets safety standards for mold, bacteria, and other contaminants. Controlled drying environment conditions should prevent microbial growth, but regular testing confirms that sanitation protocols are effective. Early detection of any contamination issues allows for corrective action before products reach consumers.

Future Innovations and Trends

The cannabis industry continues to evolve, with new technologies and techniques emerging to improve thca flower drying oregon processes. Oregon Hemp Flower Farm stays at the forefront of these developments, incorporating innovations that enhance quality while improving efficiency.

Artificial intelligence and machine learning applications are beginning to optimize controlled drying environment systems by analyzing vast amounts of environmental data to predict optimal conditions. These systems can learn from historical performance to improve future drying cycles while reducing the need for manual intervention.

Sensor technology advances provide more accurate and comprehensive monitoring of drying conditions. Wireless sensors, improved calibration methods, and new measurement techniques offer better insight into how proper drying techniques affect final product quality.

Energy efficiency improvements reduce the environmental impact and operating costs of professional drying thca facilities. Heat recovery systems, improved insulation, and more efficient equipment help reduce energy consumption while maintaining optimal drying conditions.

Sustainability initiatives focus on reducing waste, conserving resources, and minimizing environmental impact throughout the drying process. Climate control hemp operations are increasingly incorporating renewable energy, water conservation, and waste reduction strategies.

Conclusion

The art and science of thca flower drying oregon represents a critical component of premium cannabis production. Oregon Hemp Flower Farm's commitment to excellence in controlled drying environment techniques ensures that every batch of THCA flower receives optimal treatment, preserving valuable cannabinoids and terpenes while preventing spoilage or degradation.

Oregon's variable climate presents unique challenges that demand sophisticated climate control hemp solutions. Through careful attention to temperature controlled drying, humidity control hemp, and proper drying techniques, cultivators can consistently produce exceptional results regardless of external weather conditions.

The investment in professional drying thca equipment and expertise pays dividends in improved product quality, reduced waste, and enhanced consumer satisfaction. Whether working with indoor thca flower, outdoor thca flower, or greenhouse thca flower, the principles of optimal drying conditions remain consistent while allowing for customization based on specific circumstances.

Preserve quality drying requires ongoing attention to detail, continuous monitoring, and rapid response to changing conditions. Oregon Hemp Flower Farm's comprehensive approach to thca flower cultivation and drying demonstrates how dedicated professionals can consistently produce premium indoor thca products that meet the highest quality standards.

As the cannabis industry continues to mature, the importance of proper drying techniques will only increase. Consumers' growing sophistication and regulatory requirements demand consistent quality that can only be achieved through mastery of oregon drying methods and controlled drying environment techniques.

For those seeking the finest THCA flower products, Oregon Hemp Flower Farm's commitment to excellence in every aspect of cultivation and processing ensures exceptional results. Their expertise in thca flower drying oregon techniques, combined with premium genetics and careful attention to detail, produces THCA hemp flower that represents the pinnacle of cannabis quality and craftsmanship.

Leave a comment

Please note, comments need to be approved before they are published.