Small Batch THCA Flower: The Craft Cannabis Movement in Oregon

Oregon has long been recognized as a pioneer in the cannabis industry, and today, the state is leading another revolution: the craft hemp movement centered around small batch THCA Oregon cultivation. This artisanal approach to cannabis production represents a fundamental shift from mass-market growing to boutique cultivation methods that prioritize quality over quantity, creating some of the most sought-after craft hemp flower in the country.

The emergence of boutique THCA cultivation in Oregon reflects a broader cultural movement toward artisanal products across various industries. Just as craft breweries transformed the beer landscape and small-batch distilleries elevated spirits, artisan hemp growers are now redefining what premium cannabis can be. These dedicated cultivators are producing limited edition THCA strains that showcase the incredible diversity and potential of the hemp plant.

The Philosophy Behind Small Batch Cultivation

At its core, the premium small batch movement represents a return to traditional agricultural values combined with cutting-edge horticultural science. Unlike large-scale commercial operations that focus on maximizing yield and minimizing costs, micro farm THCA producers prioritize meticulous attention to detail at every stage of the growing process. This philosophy extends from seed selection to final harvest, ensuring that each plant receives individualized care and attention.

The artisanal approach begins with genetics. Handcrafted hemp flower starts with carefully selected cultivars chosen not just for their THCA content, but for their unique terpene profiles, growth characteristics, and overall quality potential. Many Oregon craft growers work with exclusive THCA strains that are either developed in-house through selective breeding programs or sourced from limited genetic libraries unavailable to commercial producers.

This dedication to genetic diversity is crucial for the oregon craft cannabis movement. While large-scale operations often focus on proven, high-yielding strains that can be grown efficiently at scale, boutique cultivators embrace the challenge of working with more temperamental genetics that require specialized care but offer unique characteristics and exceptional quality.

Indoor vs. Outdoor vs. Greenhouse: The Cultivation Trinity

Oregon's diverse climate and geography provide unique opportunities for different cultivation methods, each offering distinct advantages for small batch THCA production. The choice between indoor THCA flower, outdoor THCA flower, and greenhouse THCA flower represents one of the most important decisions for craft cultivators, with each method contributing unique characteristics to the final product.

Indoor THCA Flower: Precision and Control

Premium indoor THCA cultivation represents the pinnacle of environmental control in cannabis production. Indoor facilities allow growers to create perfectly optimized conditions for each strain, controlling every variable from light spectrum and intensity to humidity, temperature, and CO2 levels. This level of precision enables artisan growers to push plants to their genetic potential while maintaining consistency across harvests.

Indoor cultivation is particularly well-suited for exclusive THCA strains that require specific environmental conditions or are especially sensitive to external factors. The controlled environment allows growers to experiment with advanced techniques like light manipulation, targeted nutrient delivery, and stress training methods that would be impossible in outdoor settings.

The benefits of indoor cultivation extend beyond environmental control. Indoor facilities provide security, privacy, and protection from pests and diseases that can devastate outdoor crops. For small batch producers working with valuable genetics or limited plant counts, these factors are crucial for ensuring successful harvests.

However, indoor cultivation also presents challenges. The energy costs associated with artificial lighting, climate control, and ventilation systems can be substantial, making it essential for growers to maximize quality to justify the investment. This economic reality naturally aligns with the small batch philosophy, as indoor cultivation is most cost-effective when producing premium products that command higher prices.

Outdoor THCA Flower: Terroir and Natural Expression

Oregon's favorable climate makes it an ideal location for outdoor THCA flower cultivation, and many craft growers embrace the natural growing environment as an essential component of their product's character. Outdoor cultivation allows plants to express their genetics fully under natural sunlight, often resulting in more complex terpene profiles and unique characteristics that indoor environments struggle to replicate.

The concept of terroir, borrowed from wine production, plays a significant role in outdoor craft cannabis cultivation. Oregon's diverse microclimates, soil types, and environmental conditions contribute unique characteristics to outdoor-grown flower. A strain grown in the coastal regions will develop different qualities than the same genetics cultivated in the high desert or mountain valleys.

Outdoor cultivation also aligns with sustainable growing practices that many craft producers prioritize. Natural sunlight eliminates the need for energy-intensive artificial lighting, while proper soil management and organic growing practices can create closed-loop systems that minimize environmental impact.

The challenges of outdoor cultivation include weather dependency, pest pressure, and limited growing seasons. However, experienced outdoor cultivators view these challenges as opportunities to develop resilience and adaptability in their crops, often resulting in hardier plants with unique stress-induced characteristics.

Greenhouse THCA Flower: The Best of Both Worlds

Greenhouse THCA flower cultivation represents a hybrid approach that combines the benefits of natural sunlight with enhanced environmental control. Modern greenhouse facilities can provide protection from adverse weather while maintaining the benefits of solar growing, making them increasingly popular among craft cultivators.

Advanced greenhouse systems allow for precise control of temperature, humidity, and ventilation while utilizing natural sunlight as the primary light source. This approach can extend growing seasons, protect crops from extreme weather, and provide better pest management while maintaining the natural expression that many growers and consumers prefer.

The versatility of greenhouse cultivation makes it particularly attractive for small batch producers who want to experiment with different growing methods or adapt to seasonal changes. Many facilities can transition between fully natural growing during optimal weather and supplemental environmental control during challenging conditions.

The Art and Science of THCA Flower Cultivation

THCA flower cultivation represents a complex intersection of art and science, requiring both technical knowledge and intuitive understanding of plant behavior. Successful small batch cultivators combine rigorous scientific methodology with the experiential knowledge that comes from years of hands-on growing experience.

The cultivation process begins with environmental preparation. Whether working in indoor, outdoor, or greenhouse settings, craft growers must create optimal conditions for plant development. This includes soil preparation or hydroponic system design, lighting setup, ventilation planning, and pest management strategies. The attention to detail at this stage often determines the success of the entire cultivation cycle.

Genetic selection plays a crucial role in small batch production. While commercial growers often choose strains based primarily on yield and ease of cultivation, craft producers prioritize genetic diversity, unique characteristics, and quality potential. Many work with limited genetics that require specialized knowledge and techniques, viewing the additional challenge as an opportunity to create truly exceptional products.

Plant training and manipulation techniques are essential tools for small batch cultivators. Methods like low-stress training, screen of green (SCROG), and selective pruning allow growers to maximize light penetration, improve airflow, and optimize plant structure for quality production. These techniques require significant labor investment but can dramatically improve final product quality.

Nutrient management in small batch cultivation often involves custom feeding programs tailored to specific strains and growing conditions. Many craft growers develop proprietary nutrient schedules based on plant observation and testing, adjusting feeding programs throughout the growth cycle to optimize plant health and cannabinoid production.

Environmental monitoring and control systems provide the data needed for precision cultivation. Modern growing facilities utilize sensors to track temperature, humidity, light levels, and other critical parameters, allowing growers to make informed decisions and maintain optimal conditions throughout the cultivation cycle.

Quality Control and Harvesting Excellence

The small batch approach to quality control extends far beyond basic compliance testing. Craft cultivators implement comprehensive quality assurance programs that monitor plant health, environmental conditions, and product development throughout the entire cultivation cycle.

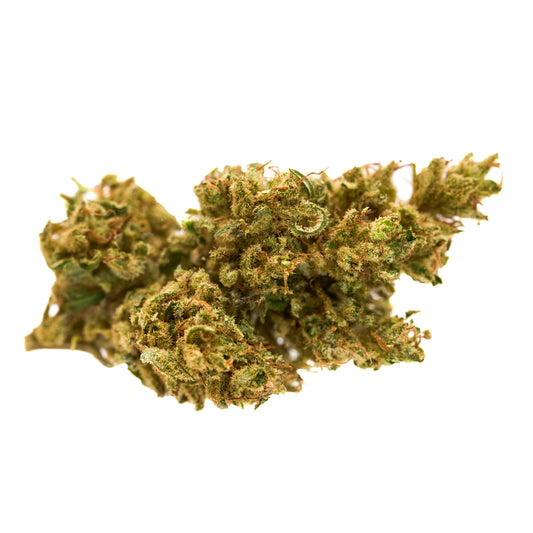

Visual inspection remains one of the most important quality control tools for experienced growers. Daily plant observation allows cultivators to identify potential issues early, monitor development progress, and make informed decisions about harvest timing and plant care. This level of attention is only possible with smaller plant counts and dedicated grower attention.

Harvest timing represents a critical decision point that can dramatically impact final product quality. While commercial operations often harvest based on scheduling and logistics considerations, craft cultivators have the flexibility to wait for optimal trichome development and peak cannabinoid production. This attention to harvest timing often distinguishes small batch products from mass-market alternatives.

Post-harvest processing requires equal attention to detail. Proper drying and curing techniques are essential for preserving terpenes, optimizing cannabinoid profiles, and creating the smooth smoking experience that characterizes premium craft flower. Small batch producers often implement extended curing processes that would be impractical for large-scale operations.

The Oregon Advantage: Climate, Culture, and Regulation

Oregon's unique combination of favorable climate, progressive cannabis culture, and reasonable regulatory framework creates an ideal environment for craft THCA cultivation. The state's diverse growing regions offer different microclimates and growing conditions, allowing cultivators to choose optimal locations for their specific strains and growing methods.

The Pacific Northwest climate provides excellent conditions for both indoor and outdoor cultivation. Mild temperatures, adequate rainfall, and long summer days create favorable growing conditions, while the region's lower humidity levels help prevent mold and mildew issues that plague growers in other regions.

Oregon's cannabis culture embraces quality and innovation, creating a market that appreciates and supports craft cultivation. Consumers in the region are educated about cannabis quality factors and willing to pay premium prices for exceptional products. This market support is essential for the economic viability of small batch cultivation.

The regulatory environment in Oregon, while complex, is generally supportive of small-scale cultivation. Licensing options for smaller operations and reasonable compliance requirements make it possible for craft growers to operate legally and profitably. This regulatory clarity provides the stability needed for long-term business development and investment in quality improvement.

Market Dynamics and Consumer Appreciation

The market for craft THCA flower reflects broader consumer trends toward premium, artisanal products. Modern cannabis consumers are increasingly sophisticated, seeking products that offer unique experiences and exceptional quality rather than simply the highest potency or lowest price.

This market evolution creates opportunities for small batch producers to differentiate their products through quality, uniqueness, and storytelling. Consumers appreciate knowing the story behind their cannabis, including growing methods, strain genetics, and cultivator philosophy. This connection between producer and consumer is often lost in mass-market products but remains strong in the craft segment.

Limited availability actually enhances the appeal of small batch products. The knowledge that a particular strain or batch may not be available again creates urgency and exclusivity that many consumers find attractive. This scarcity model allows craft producers to command premium prices while building customer loyalty and anticipation for future releases.

Quality consistency becomes a crucial factor for building brand reputation in the craft market. While small batch producers may not achieve the exact consistency of large-scale operations, they can establish quality standards and flavor profiles that customers learn to expect and appreciate.

Challenges and Opportunities in Small Batch Production

Small batch THCA cultivation faces unique challenges that differ significantly from those encountered by large-scale commercial operations. Understanding and addressing these challenges is essential for successful craft cultivation businesses.

Economic efficiency represents perhaps the greatest challenge for small batch producers. Higher per-unit production costs must be offset by premium pricing, requiring products that truly justify their higher cost through superior quality and unique characteristics. This economic reality forces craft cultivators to focus relentlessly on quality and customer satisfaction.

Scaling production while maintaining quality standards presents an ongoing challenge. As demand for craft products grows, producers face pressure to increase output without compromising the attention to detail that defines their products. Successful craft cultivators develop systems and processes that allow controlled growth while preserving quality standards.

Market education remains an important challenge and opportunity. Many consumers are still learning to appreciate the differences between craft and commercial cannabis products. Educating customers about growing methods, strain characteristics, and quality factors helps build appreciation for premium products and justifies higher prices.

Supply chain management becomes more complex for small batch producers who may work with specialized suppliers and smaller quantities of inputs. Building relationships with reliable suppliers and maintaining adequate inventory levels requires careful planning and management.

Innovation and Experimentation in Craft Cultivation

The small batch model provides unique opportunities for innovation and experimentation that are often impractical for large-scale operations. Craft cultivators can test new growing techniques, experiment with unusual genetics, and implement cutting-edge technologies without the massive investment and risk associated with scaling these innovations across large operations.

Breeding and genetic development represent exciting opportunities for craft cultivators. Working with limited plant counts and specialized genetics allows for careful selection and breeding programs that can develop unique strains with distinctive characteristics. Many of today's most sought-after cannabis strains originated from small-scale breeding programs.

Sustainable growing practices often find their initial application in craft cultivation. Organic growing methods, renewable energy systems, and closed-loop growing systems can be tested and refined in small batch operations before being scaled to larger facilities. This innovation often drives industry-wide improvements in sustainability and environmental responsibility.

Technology integration in small batch cultivation often focuses on precision and data collection rather than automation and scale. Monitoring systems, environmental controls, and analysis tools help craft cultivators optimize their growing processes and document the factors that contribute to exceptional quality.

The Future of Craft THCA Cultivation

The craft cannabis movement in Oregon and beyond shows strong momentum and continued growth potential. As cannabis markets mature and consumers become more sophisticated, demand for premium, artisanal products is likely to increase rather than diminish.

Regulatory evolution may create new opportunities for craft cultivators. Potential changes in federal cannabis law could open new markets and distribution channels, while continued refinement of state regulations may reduce compliance burdens and operational costs.

Technology development specifically targeted at small batch cultivation could further improve quality and efficiency. Advances in LED lighting, environmental control systems, and monitoring technologies may make high-quality cultivation more accessible and cost-effective for craft producers.

Market expansion beyond local and regional boundaries could significantly increase opportunities for craft cultivators. As shipping and distribution networks develop, exceptional small batch products may find markets across the country, supporting the economic viability of craft cultivation.

Building Community and Culture

The craft THCA movement extends beyond simple commercial cultivation to encompass community building and cultural development. Many craft cultivators view themselves as stewards of cannabis culture, preserving traditional growing knowledge while advancing the art and science of cultivation.

Education and knowledge sharing play important roles in the craft cultivation community. Experienced growers often mentor newcomers, sharing techniques and insights that help maintain quality standards across the craft segment. This collaborative approach strengthens the entire craft cultivation community.

Events and competitions showcase the best of craft cultivation while providing opportunities for growers to learn from each other and gain recognition for their work. Cannabis cups, harvest festivals, and cultivation competitions help build community and drive continued improvement in quality and innovation.

Consumer education remains a crucial component of community building. Craft cultivators often engage directly with customers through farm tours, educational events, and detailed product information. This direct connection helps build appreciation for craft cultivation and supports premium pricing.

Conclusion: The Continuing Evolution of Craft Cannabis

The small batch THCA movement in Oregon represents a fundamental shift in how we think about cannabis cultivation and consumption. By prioritizing quality over quantity and embracing traditional agricultural values combined with modern growing science, craft cultivators are creating products that showcase the true potential of the cannabis plant.

As the industry continues to mature, the craft segment is likely to play an increasingly important role in defining quality standards and driving innovation. The dedication, passion, and expertise of small batch cultivators ensure that consumers will continue to have access to exceptional cannabis products that reflect the artistry and science of expert cultivation.

For those interested in experiencing the finest examples of craft THCA cultivation, Oregon Hemp Flower Farm offers an exceptional selection of small batch, artisan-grown THCA flower that exemplifies the quality and care that defines the craft cannabis movement. Each product represents the dedication and expertise of skilled cultivators who have chosen quality over quantity, creating truly exceptional cannabis experiences for discerning consumers.

The future of cannabis lies not in mass production and commoditization, but in the continued pursuit of excellence through craft cultivation methods that honor both the plant and the consumer. Oregon's craft THCA movement stands as a testament to what is possible when passion, expertise, and dedication combine to create truly exceptional cannabis products.

Leave a comment

Please note, comments need to be approved before they are published.