How THCA Indoor Flower is Grown: From Seed to Harvest

The world of THCA indoor growing has revolutionized the cannabis industry, producing some of the highest quality flower available today. Understanding the intricate process of how to grow THCA flower indoors is essential for both cultivators and consumers who want to appreciate the craftsmanship behind premium cannabis products. This comprehensive guide will take you through every stage of indoor cannabis cultivation, from selecting the perfect genetics to harvesting potent, trichome-covered buds.

Indoor cultivation has become the gold standard for THCA flower production because it allows growers to maintain complete control over environmental factors that directly impact cannabinoid development. Unlike outdoor growing, where weather, pests, and seasonal limitations can compromise quality, controlled environment growing ensures consistent, premium results every harvest. The ability to manipulate lighting schedules, maintain optimal temperatures, and create perfect humidity conditions makes indoor facilities the preferred method for producing high-THCA flower that meets today's demanding standards.

The journey from seed to harvest is a meticulous process that typically spans 3-6 months, depending on the strain and growing methods employed. Each stage requires specific attention to detail, from the initial germination phase through the final curing process. Professional cultivators understand that every decision made during this timeline directly impacts the final product's potency, flavor profile, and overall quality. This is why premium THCA indoor flower commands higher prices and delivers superior experiences compared to outdoor alternatives.

Setup and Environment Control: The Foundation of Excellence

Creating the perfect environment for THCA indoor growing begins with sophisticated climate control systems that maintain precise conditions throughout the entire grow cycle. Professional facilities invest heavily in HVAC systems capable of maintaining temperatures within a narrow range of 68-78°F during the day and slightly cooler at night. These temperature fluctuations mimic natural conditions while preventing stress that could reduce THCA production.

The heart of any indoor farm setup lies in its lighting system. Modern LED grow lights have replaced traditional HPS and metal halide fixtures due to their superior efficiency and spectrum control capabilities. High-quality LED systems produce photosynthetic photon flux densities (PPFD) ranging from 400-800 μmol/m²/s during vegetative growth and up to 1,000-1,200 μmol/m²/s during flowering. The ability to adjust light spectrums throughout different growth stages is crucial for maximizing trichome development and THCA synthesis.

Humidity control represents another critical component of successful controlled environment growing. During the seedling and vegetative stages, relative humidity should be maintained between 60-70% to promote healthy growth and prevent stress. As plants transition into flowering, humidity levels must be gradually reduced to 40-50% to prevent mold and mildew while encouraging resin production. Professional facilities utilize commercial dehumidifiers and humidifiers connected to automated control systems that make real-time adjustments based on sensor feedback.

Air circulation requirements for indoor cannabis cultivation cannot be overstated. Proper airflow prevents hot spots, reduces humidity pockets, and strengthens plant stems through gentle movement. Industrial-grade exhaust fans should provide complete air exchange every 1-3 minutes, while oscillating fans create consistent air movement throughout the canopy. Carbon filtration systems not only control odors but also help maintain clean air quality essential for producing premium flower.

The debate between hydroponic THCA cultivation and traditional soil methods often comes down to control versus tradition. Hydroponic systems offer precise nutrient delivery and faster growth rates, typically reducing total grow time by 2-3 weeks. However, many cultivators prefer organic soil methods for their ability to enhance terpene profiles and create more complex flavor profiles. Premium THCA flower production facilities often utilize living soil systems that combine the benefits of both approaches, providing precise control while maintaining the natural biological processes that enhance cannabinoid and terpene development.

Water quality forms the foundation of any successful growing operation. Professional facilities invest in reverse osmosis systems to ensure water purity, then carefully adjust pH levels to the optimal range of 6.0-7.0 for soil or 5.5-6.5 for hydroponics. Water temperature should be maintained between 65-75°F to promote healthy root development and nutrient uptake. The electrical conductivity (EC) of nutrient solutions must be monitored continuously, as fluctuations can stress plants and reduce THCA production.

Genetics and Strain Selection: The Blueprint for Potency

Selecting the right cannabis genetics is perhaps the most crucial decision in THCA flower production. High-THCA strains are specifically bred to maximize the production of tetrahydrocannabinolic acid, the precursor to THC that remains stable until exposed to heat or UV light. These genetics often originate from carefully selected phenotypes of popular strains that have been stabilized through multiple generations of breeding.

Modern breeding programs focus on developing cannabis genetics that not only produce high THCA levels but also maintain stability under controlled indoor conditions. Breeders look for traits such as compact structure, early flowering, disease resistance, and consistent cannabinoid production. The most successful THCA strains for indoor cannabis cultivation typically exhibit strong hybrid vigor, meaning they perform well under artificial lighting and respond positively to training techniques.

Popular THCA-rich strains dominating today's market include specially bred phenotypes of Wedding Cake, Gelato, Purple Punch, and various OG Kush derivatives. These strains have been selected not only for their high THCA content, which can exceed 25% in optimal conditions, but also for their ability to develop dense, resinous flowers under LED grow lights. Each strain presents unique challenges and requirements, from specific nutrient preferences to optimal harvest timing windows.

The decision between starting from seeds versus clones significantly impacts the THCA indoor growing process. Seeds offer genetic diversity and the potential to discover exceptional phenotypes, but require additional time for phenotype selection and mother plant identification. Clones provide genetic consistency and faster time to harvest but may carry diseases or genetic weaknesses from the mother plant. Professional facilities often maintain comprehensive mother plant libraries, preserving the genetics of their highest-performing THCA producers.

Phenotype hunting represents a critical aspect of developing a successful indoor cannabis cultivation program. This process involves growing multiple plants from the same strain, evaluating their performance across various metrics including THCA production, terpene profiles, growth characteristics, and overall yield. The best-performing phenotypes are then selected as mother plants for future clone production, ensuring consistency in quality and potency across harvests.

Genetic stability becomes increasingly important as cultivation scales up. Unstable genetics can lead to hermaphroditic plants that produce seeds, ruining entire harvests and contaminating other plants in the facility. Professional breeders invest years in stabilizing their cannabis genetics through careful selection and breeding programs that eliminate unwanted traits while enhancing desirable characteristics like high THCA production and terpene complexity.

Growth Stages: Nurturing Excellence Through Each Phase

Seedling Stage: The Foundation (2-3 weeks)

The seedling stage marks the beginning of the THCA flower production journey, requiring careful attention to create optimal conditions for healthy root and shoot development. During this critical 2-3 week period, young plants are most vulnerable to environmental stress and require gentle handling to establish strong foundations for future growth.

Light requirements during the seedling stage are significantly lower than later growth phases. LED grow lights should provide PPFD levels between 200-400 μmol/m²/s, positioned 24-36 inches above the canopy to prevent light burn. The photoperiod should be set to 18-24 hours of light per day to encourage rapid vegetative growth. Many experienced growers prefer 20/4 light cycles, providing plants with a brief rest period that can improve overall health and development.

Watering schedules during the seedling stage require a delicate balance between maintaining adequate moisture and preventing overwatering, which is one of the most common causes of seedling failure in THCA indoor growing. Young plants should be watered when the growing medium feels dry about one inch below the surface. Watering should be done slowly and evenly, allowing the water to penetrate the growing medium without creating waterlogged conditions that can lead to root rot.

Nutrient requirements for seedlings are minimal, as most quality growing mediums contain sufficient nutrients for the first 1-2 weeks of growth. When nutrients are introduced, they should be diluted to 25-50% of the recommended strength for mature plants. Early feeding programs focus on providing balanced nutrition with slightly higher nitrogen content to support rapid vegetative growth essential for establishing strong cannabis genetics.

Environmental conditions during the seedling stage should favor slightly higher humidity levels (65-70%) to prevent transplant shock and encourage healthy development. Temperature should be maintained at 75-80°F during light periods and no more than 5-10 degrees cooler during dark periods. These conditions mimic the warm, humid environment that young cannabis plants prefer in nature while preventing the stress that can permanently impact final THCA production.

Vegetative Stage: Building Structure (4-8 weeks)

The vegetative stage represents the primary growth phase of controlled environment growing, lasting 4-8 weeks depending on the desired plant size and training techniques employed. During this phase, plants focus entirely on developing strong stems, healthy root systems, and abundant foliage that will support heavy flower production during the later flowering stage.

Training techniques during the vegetative stage are crucial for maximizing yield and optimizing light penetration in indoor cannabis cultivation. Low-stress training (LST) involves gently bending and securing branches to create an even canopy that maximizes light exposure to all flowering sites. Screen of Green (ScrOG) methods use horizontal screens to train plants into flat, uniform canopies that make efficient use of LED grow lights.

Pruning methods play a significant role in directing plant energy toward the development of premium flowering sites. Topping, which involves removing the main growing tip, encourages plants to develop multiple primary branches and creates bushier growth patterns ideal for indoor farm setup conditions. Defoliation, when performed correctly, removes excess fan leaves that block light penetration to lower flowering sites, potentially increasing overall THCA production.

Nutrient adjustments during the vegetative stage focus on providing higher nitrogen levels to support rapid leaf and stem development. Professional THCA flower production facilities typically use nutrient solutions with N-P-K ratios around 3-1-2, providing plants with the building blocks necessary for robust vegetative growth. Calcium and magnesium supplementation becomes increasingly important, especially in hydroponic systems where these nutrients can be easily depleted.

Light intensity during the vegetative stage should be gradually increased from seedling levels to 600-800 μmol/m²/s PPFD. The photoperiod remains at 18-24 hours of light per day, with many cultivators preferring 18/6 schedules that provide plants with adequate rest periods for metabolic processes. Modern LED grow lights allow for spectrum adjustments, with vegetative growth benefiting from higher blue light ratios that promote compact, sturdy growth.

Environmental control during vegetation requires maintaining temperatures between 70-78°F during light periods and 65-70°F during dark periods. Humidity should be maintained at 55-65% to prevent mold issues while supporting healthy transpiration. Air circulation becomes increasingly important as plants develop larger canopies that can trap moisture and create microclimates within the growing space.

Flowering Stage: The Final Push (8-12 weeks)

The flowering stage represents the culmination of THCA indoor growing efforts, typically lasting 8-12 weeks depending on the specific cannabis genetics being cultivated. This phase is triggered by changing the photoperiod to 12 hours of light and 12 hours of uninterrupted darkness, mimicking the natural seasonal changes that signal plants to begin reproductive processes.

Light cycle changes mark the beginning of the most critical phase in THCA flower production. The transition to 12/12 lighting must be absolute, with any light leaks during dark periods potentially causing plants to revert to vegetative growth or develop hermaphroditic traits. Professional facilities invest in light-proof environments and backup power systems to ensure consistent dark periods throughout the flowering phase.

Trichome development accelerates dramatically during the flowering stage, with plants producing increasing amounts of resinous glands that contain high concentrations of THCA and other cannabinoids. Environmental conditions during this phase directly impact trichome production, with slightly cooler temperatures (65-75°F) and lower humidity (40-50%) encouraging resin production while preventing mold development.

Light intensity during flowering should reach peak levels of 800-1,200 μmol/m²/s PPFD to drive maximum photosynthesis and energy production. LED grow lights configured for flowering typically emphasize red spectrum wavelengths that promote flower development and resin production. Some cultivators employ UV supplementation during the final weeks of flowering to stress plants and potentially increase THCA production.

Nutrient requirements shift dramatically during flowering, with plants requiring higher phosphorus and potassium levels to support flower development. Professional controlled environment growing operations typically use bloom-specific nutrient formulations with N-P-K ratios around 1-3-2. Calcium and sulfur supplementation becomes crucial for supporting the heavy metabolic demands of flower and resin production.

Harvest timing indicators require careful observation of trichome development using jeweler's loupes or microscopes. Peak THCA production typically occurs when trichomes transition from clear to cloudy, with approximately 10-20% beginning to turn amber. Harvesting too early results in lower THCA levels, while waiting too long can lead to degradation of cannabinoids and loss of potency.

Harvest and Post-Processing: Preserving Excellence

Optimal harvest timing represents one of the most critical decisions in THCA flower production, directly impacting final potency, flavor, and overall quality. Professional cultivators monitor trichome development daily during the final weeks of flowering, looking for the optimal window when THCA production peaks. The harvest window typically spans 7-10 days, during which different plants may reach peak maturity at different times.

Environmental conditions during harvest significantly impact the preservation of THCA and terpenes. Harvesting should be conducted in cool, dark conditions to prevent degradation of sensitive compounds. Many professional facilities harvest during the dark cycle when plants have not been exposed to LED grow lights for several hours, theoretically preserving higher levels of temperature-sensitive compounds.

Drying techniques for THCA indoor growing require precise environmental control to prevent mold development while preserving cannabinoid and terpene profiles. Ideal drying conditions include temperatures between 60-70°F with humidity levels maintained at 45-55%. Air circulation should be gentle but consistent, providing fresh air exchange without directly blowing on hanging flowers. The drying process typically takes 7-14 days, depending on flower density and environmental conditions.

Proper drying techniques involve hanging whole branches or individual colas in climate-controlled drying rooms equipped with dehumidifiers, air conditioning, and circulation fans. The goal is to slowly reduce moisture content from approximately 75% to 10-15% while preserving the integrity of trichomes and preventing the degradation of THCA. Many facilities use commercial drying systems that maintain precise environmental conditions throughout the entire process.

The curing process begins once flowers reach optimal moisture content, typically indicated when smaller stems crack when bent but larger stems still bend. Properly dried flowers are carefully trimmed to remove excess leaf material before being placed in airtight containers for the curing phase. Curing containers should be filled no more than 75% full to allow adequate air circulation during the process.

THCA preservation methods during curing focus on maintaining stable environmental conditions while allowing for controlled gas exchange that promotes proper curing. Containers should be opened daily for the first week, then less frequently as the cure progresses. Relative humidity within curing containers should be maintained at 58-62%, often achieved using humidity control packs. The curing process typically lasts 2-8 weeks, with longer cures generally producing superior flavor and aroma profiles.

Temperature control during curing should maintain consistent cool conditions, ideally 60-68°F, to prevent THCA degradation and preserve terpene profiles. Light exposure should be minimized during storage and curing, as UV radiation can degrade THCA and other cannabinoids. Professional facilities often cure their THCA indoor flower in dark, temperature-controlled rooms specifically designed for post-harvest processing.

Quality control measures throughout the curing process include regular moisture content testing, visual inspection for mold development, and periodic sampling for potency testing. Properly cured THCA flower production should maintain stable moisture content, exhibit enhanced terpene profiles, and preserve high levels of THCA that can exceed 25% in well-grown examples.

Quality Indicators and Consumer Considerations

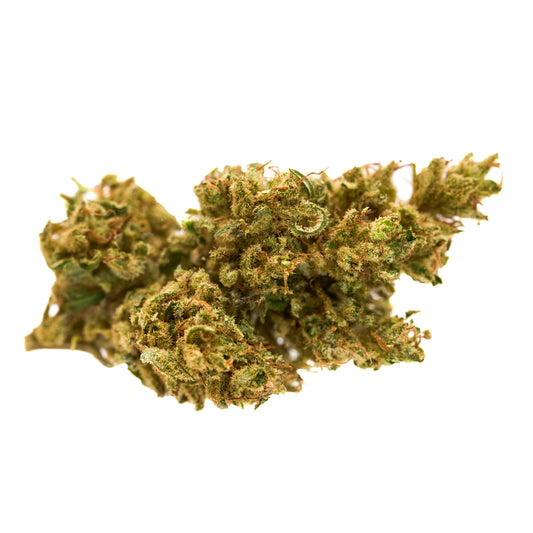

Understanding quality indicators in THCA indoor flower helps consumers make informed purchasing decisions and appreciate the craftsmanship behind premium products. Visual indicators include dense, well-formed flowers covered in a thick layer of trichomes that give the buds a frosty, crystal-covered appearance. The presence of orange or purple pistils, depending on the strain genetics, indicates proper maturation and harvest timing.

Aroma profiles in high-quality indoor cannabis cultivation products should be complex and pronounced, reflecting the careful preservation of terpenes throughout the growing and curing process. Well-cured flowers exhibit rich, layered aromas that can range from fruity and sweet to earthy and fuel-like, depending on the specific cannabis genetics and cultivation techniques employed.

Texture and moisture content provide important clues about proper cultivation and curing practices. Premium THCA flower production should feel slightly sticky to the touch due to resin content while maintaining structural integrity. Properly cured flowers should not be overly dry or brittle, nor should they feel moist or spongy, both of which indicate problems with the drying and curing process.

The importance of controlled environment growing becomes evident when comparing indoor products to outdoor alternatives. Indoor cultivation allows for consistent quality, higher potency levels, and cleaner products free from environmental contaminants such as pesticides, mold, and outdoor pollutants. The controlled nature of indoor growing ensures that every harvest meets the same high standards that consumers expect from premium cannabis products.

Laboratory testing results provide objective measures of quality in THCA indoor growing products. Comprehensive testing should include cannabinoid profiles showing THCA levels, terpene analysis revealing flavor and aroma compounds, and safety testing for pesticides, heavy metals, microbials, and residual solvents. Premium indoor flower typically tests between 20-30% total THCA, with some exceptional examples exceeding these levels.

Packaging and storage considerations for maintaining THCA quality include light-proof containers that prevent UV degradation, airtight seals that preserve terpene profiles, and proper humidity control to prevent mold development or over-drying. Professional packaging often includes humidity control packs and nitrogen flushing to create optimal storage environments that preserve quality from harvest to consumption.

Conclusion

The art and science of THCA indoor growing represents the pinnacle of cannabis cultivation, combining advanced technology with traditional growing wisdom to produce exceptional flower. Understanding how to grow THCA flower indoors requires mastery of environmental control, genetics selection, and post-harvest processing techniques that preserve and enhance the natural qualities of premium cannabis.

The controlled environment of indoor cannabis cultivation facilities allows cultivators to optimize every aspect of plant development, from seedling through harvest. The precision possible with modern LED grow lights, climate control systems, and monitoring technology ensures consistent results that meet the demanding standards of today's cannabis connoisseurs.

Professional THCA flower production requires significant investment in infrastructure, expertise, and attention to detail throughout every stage of the growing process. The complexity of controlled environment growing explains why premium indoor flower commands higher prices and delivers superior experiences compared to outdoor alternatives.

For consumers seeking the highest quality THCA indoor flower, understanding the cultivation process provides valuable insight into what makes exceptional cannabis products. The combination of superior genetics, optimal growing conditions, and careful post-harvest processing creates products that represent the best of modern cannabis cultivation.

The future of indoor cannabis cultivation continues to evolve with advancing technology and improved understanding of plant biology. As the industry matures, consumers can expect even higher quality products from dedicated cultivators who view THCA flower production as both an art and a science, combining passion with precision to create truly exceptional cannabis experiences.

Frequently Asked Questions

Q: How long does it take to grow THCA flower indoors from seed to harvest? A: The complete THCA indoor growing cycle typically takes 3-6 months, including 2-3 weeks for seedling development, 4-8 weeks of vegetative growth, and 8-12 weeks of flowering, depending on the specific genetics and growing methods used.

Q: What makes indoor THCA flower superior to outdoor cultivation? A: Controlled environment growing allows precise control over lighting, temperature, humidity, and nutrients, resulting in higher potency, cleaner products, and consistent quality that outdoor cultivation cannot match due to weather variables and environmental factors.

Q: What type of lighting is best for THCA flower production? A: Modern LED grow lights are preferred for indoor cannabis cultivation due to their energy efficiency, spectrum control, and ability to provide optimal PPFD levels ranging from 800-1,200 μmol/m²/s during flowering.

Q: How can consumers identify high-quality THCA indoor flower? A: Quality indicators include dense, trichome-covered buds with complex aromas, proper moisture content, laboratory testing showing high THCA levels (20-30%), and clean cultivation practices evidenced by the absence of contaminants and proper curing techniques.

Q: What role does genetics play in THCA flower production? A: Cannabis genetics determine the maximum THCA potential, growth characteristics, and terpene profiles of the final product. Professional cultivators select and breed specific phenotypes that perform well under indoor conditions and produce consistently high THCA levels.

Q: Why is the curing process important for THCA preservation? A: The curing process allows for controlled moisture reduction while preserving THCA and terpenes, enhancing flavor and aroma profiles, and creating the optimal texture and smoking characteristics that consumers expect from premium indoor flower.

Leave a comment

Please note, comments need to be approved before they are published.